Our Custom Plastic Fabrication Services

Bringing your ideas to reality through cutting-edge custom plastic fabrication and production solutions.

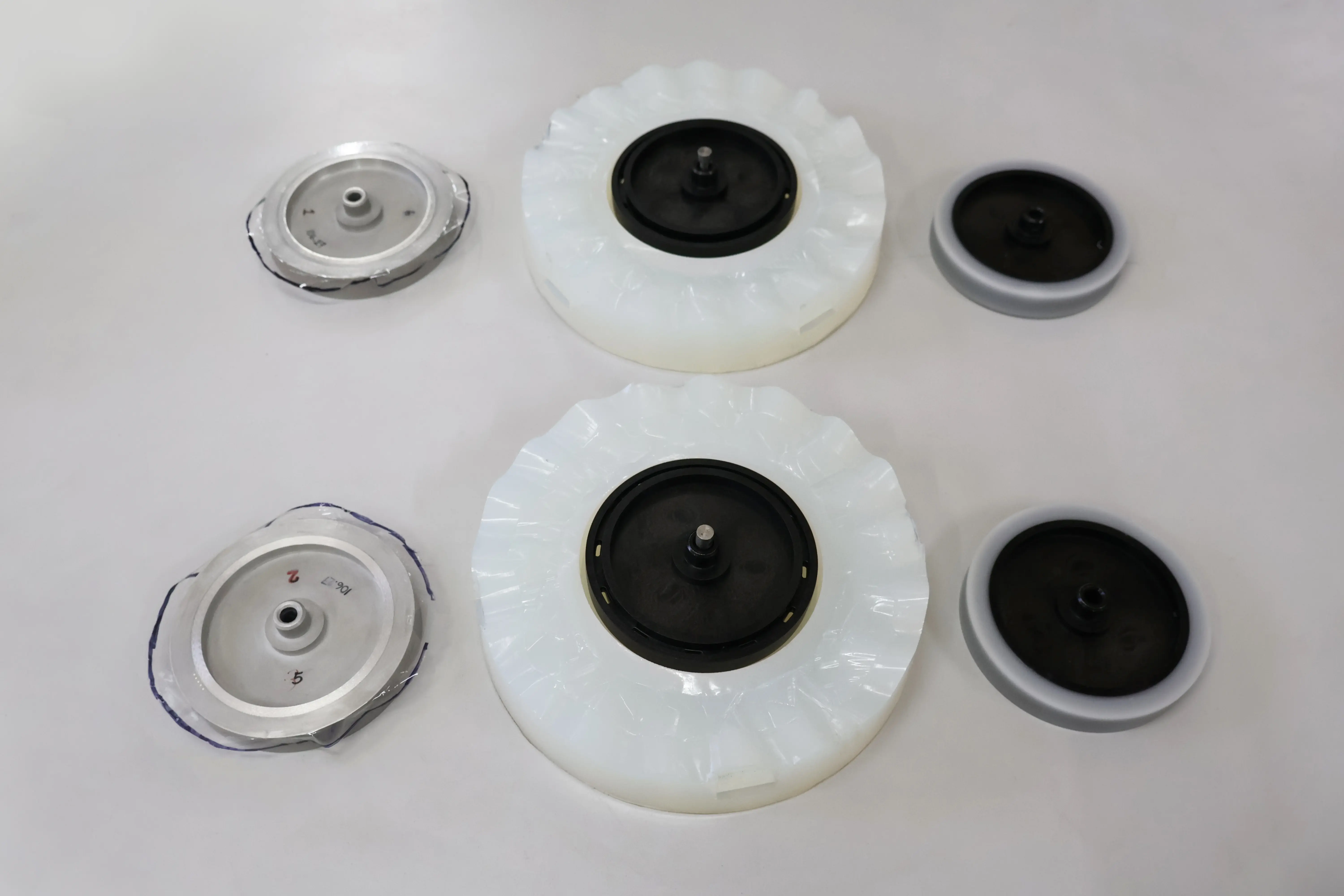

Silicone Molding

Expert silicone mold and urethane casting services for high-quality custom plastic fabrication and small-batch production.

Learn More3D Printing

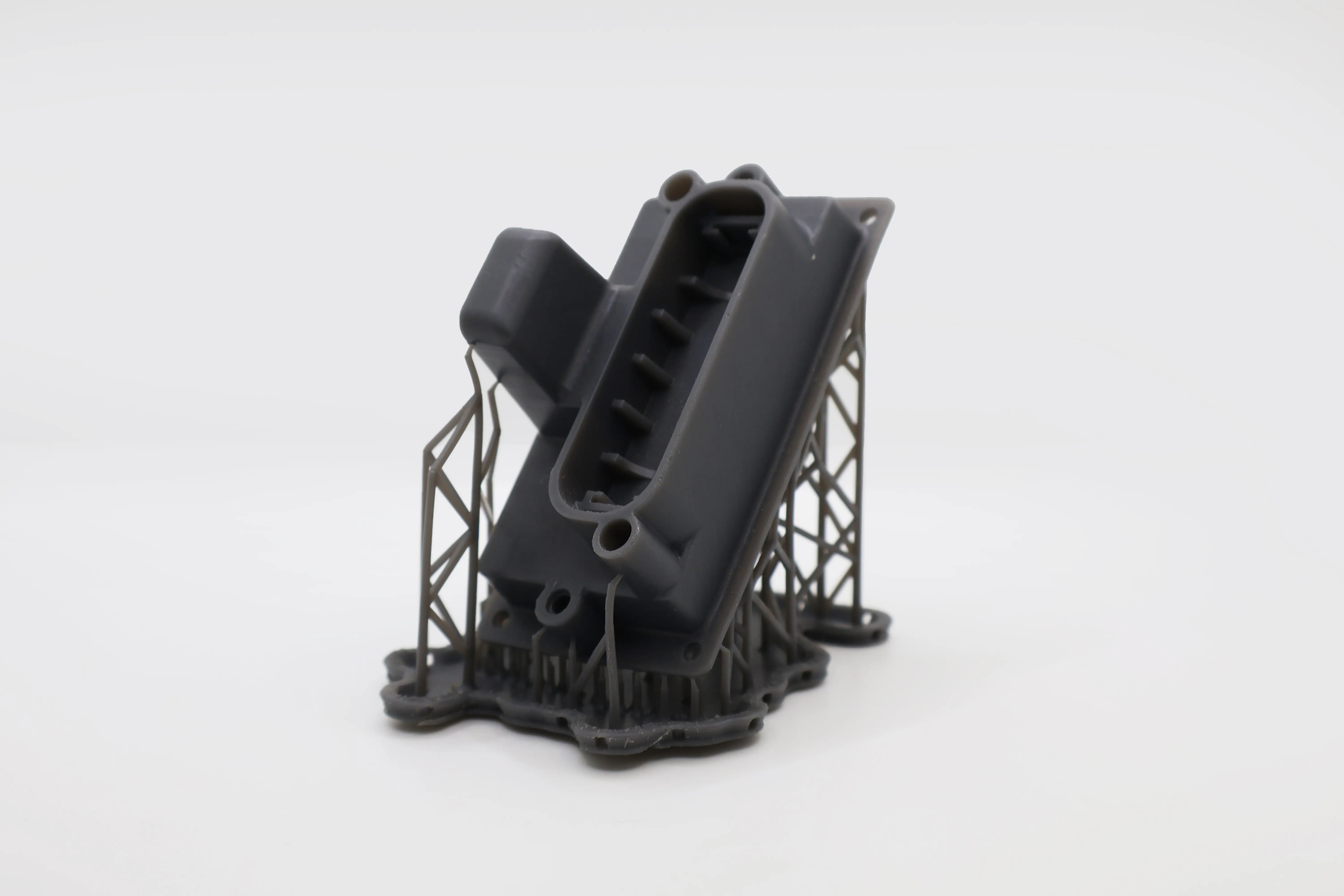

Advanced 3D printing solutions offering precision-engineered prototypes with superior detail and accuracy.

Learn MoreCustom Plastic Fabrication Services

Comprehensive custom plastic fabrication solutions to accelerate innovation and enhance product development.

Learn MoreOur Portfolio

Explore our recent projects that highlight our expertise in delivering high-quality custom plastic fabrication, innovative designs, and precision-engineered solutions across various industries.

- All

- 3D Printed Parts

- Urethane Casted Overmolding

- Urethane Casted Parts

Why Choose Us

Why Choose Us

Discover what sets us apart and why our clients trust us to deliver excellence.

Innovative Products

We deliver high-quality, cutting-edge solutions designed to meet evolving market demands.

Proven Methodology

Our strategic and detail-oriented approach guarantees efficient and effective outcomes.

Competitive Pricing

We offer cost-effective solutions without compromising quality, ensuring maximum value for your investment.

Timely Delivery

Our streamlined processes and efficient project management ensure on-time delivery, every time.

Dedicated Support

We provide ongoing assistance and expert guidance to ensure seamless project execution and customer satisfaction.

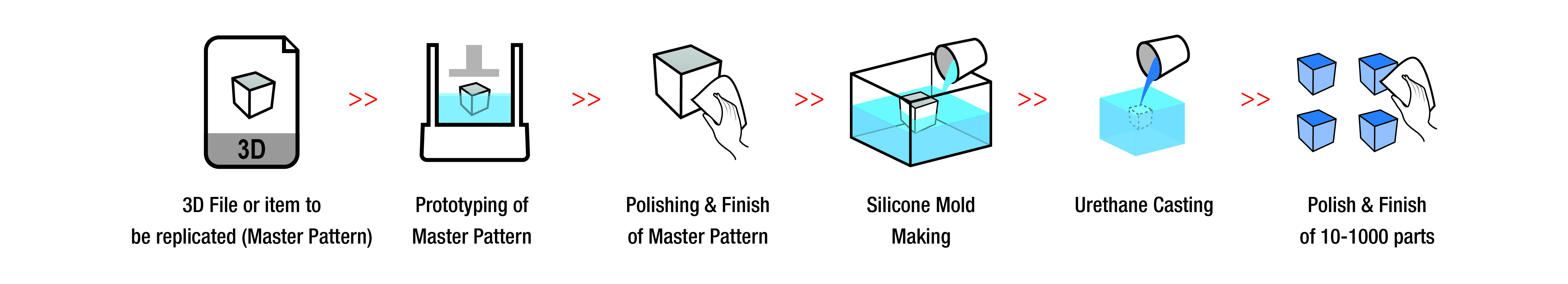

Our Process

Our method ensures accuracy, quality, and efficiency from start to finish.

232

Happy Clients

521

Completed Projects

453

Hours of Support

Frequently Asked Questions

Your questions answered clearly and effectively

- General Purpose Resin

- Tough Resin - equivalent to ABS thermoplastic material

- Castable Resin - equivalent to wax used in investment casting

- High-Temp Resin - has Heat Deflection Temperature (HDT) of 289 °C

- Flexible Resin - equivalent to Rubber at an 80 Shore A rating.

- Durable Resin - equivalent to Polypropylene (PP) thermoplastic material.

We offer various urethane casting materials, such as:

Rigid plastics: ABS, POM, and Polycarbonate, ensuring durability of the parts.

Flexible material: Rubber-like options are suitable for high-impact applications.

- Material versatility: materials like ABS, Polycarbonate, and Rubber serve as an alternative that replicates popular engineering materials.

- Higher precision: Produces parts with tighter tolerances.

- Faster production: Once molds are made, parts can be produced quickly in small batches.

- Cost- effective for small volume productions: The cost per part decreases significantly when producing 10 to a few hundred parts, making it a more affordable option than 3D printing when producing small production quantities.

We can produce urethane-cast parts up to 450 x 450 x 450 mm in a single casting and guarantee a minimum thickness of 1.5mm.

Also, our urethane-cast parts can incorporate inserts, undergo over-molding, and be post-processed (e.g., painted) to meet specific functional and aesthetic requirements.

Let's Discuss your Projects

You can get started by contacting us with your project details and specifications. Our team will assess your needs and guide you through the custom plastic fabrication process.

Contact Us